Listen to the article

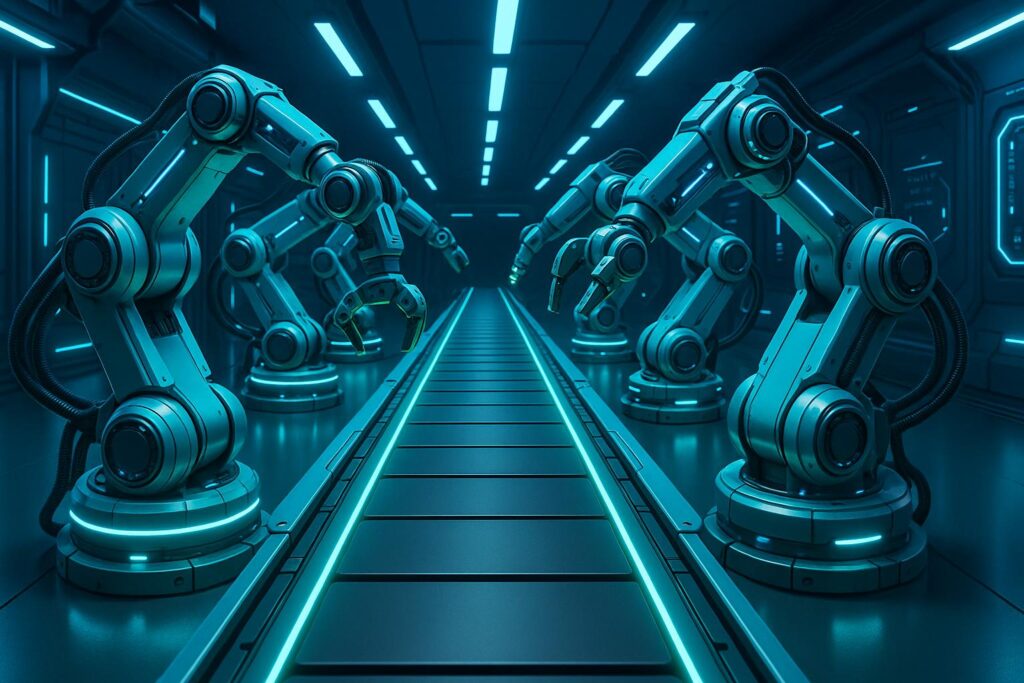

The global market for smart magnetic drive conveyor systems is expected to grow significantly over the next decade, driven by advancements in automation, AI integration, and a rising demand for hygienic, flexible manufacturing solutions across sectors including food, pharmaceuticals, and automotive.

The global smart magnetic drive conveyor system market is poised for significant growth over the coming decade, with its valuation expected to jump from USD 2.3 billion in 2025 to approximately USD 3.9 billion by 2035. This represents an absolute increase of about USD 1.5 billion and a compound annual growth rate (CAGR) of 5.1%. The market’s expansion is propelled by increasing automation requirements in manufacturing, the adoption of flexible production systems, and a stronger emphasis on precision material handling and energy efficiency. Such systems are crucial across diverse sectors, including food and beverage, pharmaceuticals, automotive, and electronics manufacturing.

Forecasts indicate that between 2025 and 2030, the market will grow by USD 517 million, a testament to rising Industry 4.0 adoption and smart factory implementation. This period will witness increasing demand for conveyors compatible with cleanroom environments, particularly within pharmaceutical and electronics production. The focus on flexible line configurations and individualized product tracking is prompting suppliers and automation integrators to enhance magnetic conveyor capabilities, facilitating real-time production optimisation and mass customisation. By the latter half of the decade, from 2030 to 2035, growth is expected to accelerate, driven by greater integration of artificial intelligence, enabling predictive maintenance and autonomous production control. Modular platform designs allowing rapid reconfiguration and eco-friendly manufacturing initiatives prioritising energy-efficient material handling will further fuel expansion.

The smart magnetic conveyor market has historically gained traction as manufacturers recognized the technology’s advantages over mechanical systems, including eliminating mechanical wear, enabling precise tracking, and meeting hygiene standards critical for stringent food safety and pharmaceutical regulations. Linear motor advancements and distributed control systems have emphasized precise positioning and seamless integration with manufacturing execution systems, underpinning the system’s rising acceptance.

In terms of system design, single-track configurations dominate the market, accounting for 61.7% of the share in 2025. Their simplified architecture, cost-effectiveness, and ability to deliver independent product control while optimising space make them highly attractive for manufacturing environments prioritising flexible material handling and compact production layouts. This configuration also serves as an accessible entry point for manufacturers transitioning from traditional mechanical conveyors.

The food and beverage sector emerges as the leading application, capturing 44.3% of the market share. This dominance is due to the critical need for hygienic, contamination-free material handling facilitated by magnetic drive’s contactless technology. The systems’ stainless steel construction and washdown compatibility align perfectly with food safety standards, supporting beverage bottling, dairy processing, confectionery production, and flexible packaging demands. Growth in packaged food consumption and evolving production formats further bolster demand for smart magnetic conveyors in this sector.

Key market drivers include the intensifying trend towards mass customization and the concomitant need for flexible manufacturing systems capable of dynamic product routing and rapid changeovers. Additionally, increasing regulatory focus on hygiene within food and pharmaceutical production incentivises the adoption of conveyor systems offering contactless drive technology. However, the market faces challenges such as high initial capital costs, complexity in system integration and programming, and competition from established mechanical conveyor systems.

Geographically, East Asia, South Asia, and Europe are the leading growth regions. China stands out with a projected CAGR of 6.9%, supported by extensive manufacturing automation investments under the “Made in China 2025” initiative, pharmaceutical and food processing expansion, and broad smart factory adoption. India follows closely with a 6.4% CAGR, driven by growing pharmaceutical exports, manufacturing sector expansion, and increasing automation adoption. Germany also shows robust growth at 5.9%, benefiting from its industrial leadership in automotive production and Industry 4.0 integration.

Other significant markets include Brazil, emphasising food processing expansion and industrial automation growth; the United States, focusing on pharmaceutical production automation, food safety compliance, and manufacturing reshoring; the United Kingdom, with a concentration on pharmaceutical excellence and food processing; and Japan, known for its advanced automation culture and precision manufacturing.

Europe’s market is forecasted to grow from USD 642.8 million in 2025 to USD 1 billion by 2035. Germany leads the region, followed by France, the United Kingdom, Italy, Spain, and Switzerland, each demonstrating strong performance driven by specific industry focuses such as pharmaceuticals and food processing.

The competitive landscape is diverse, with key players including Bosch Rexroth, Beckhoff, LS Electric, Rockwell International, and B&R Industrial leading the charge alongside notable Chinese manufacturers like Guangzhou Yinuo Intelligent Technology. These companies emphasize modular designs, Industry 4.0 integration, energy efficiency, and advanced commissioning tools to meet evolving buyer demands. Innovations in artificial intelligence integration and predictive maintenance features are also becoming critical differentiators.

Industry experts note that expanding safety standards, hygiene regulations, performance specifications, and energy efficiency benchmarks will further solidify market growth. Industry associations and manufacturing end-users play vital roles in setting technical guidelines, certification programs, and performance benchmarking, facilitating broader adoption. Moreover, research institutions and financial stakeholders contribute by advancing control algorithms, energy-efficient technologies, and by providing investment support to lower entry barriers for smaller manufacturers.

In summary, the smart magnetic drive conveyor system market is on a growth trajectory fueled by technological advancement, regulatory demands, and the shift towards flexible, intelligent manufacturing. Its role in enabling hygienic, energy-efficient, and highly customizable production environments positions it as a critical component of modern industrial automation strategies worldwide.

📌 Reference Map:

- [1] (Future Market Insights) – Paragraphs 1-12

Source: Fuse Wire Services